Acrylic vs. Polycarbonate: A Complete Guide to Choosing the Right Material for Your Project

When embarking on a project that requires transparent or translucent materials, two popular choices come to mind: acrylic and polycarbonate. While they may look similar at first glance, these materials have distinct differences that can impact their performance, durability, and cost. Whether you're constructing a greenhouse, installing windows, or building displays, knowing the strengths and weaknesses of each material is crucial to choosing the right one for your project.

In this guide, we’ll break down the key differences between acrylic and polycarbonate, covering their properties, applications, pros, and cons to help you make the most informed decision.

What is Acrylic?

Acrylic, also known as Plexiglas® or Lucite®, is a transparent thermoplastic known for its optical clarity and lightweight nature. It is commonly used as a substitute for glass in a variety of applications.

Key Properties of Acrylic:

- Transparency: Acrylic sheets offer exceptional light transmission, up to 92%, making them ideal for clear, visually appealing displays and windows.

- Strength: Though not as strong as polycarbonate, acrylic is still 10 times stronger than glass, providing impact resistance without the risk of shattering.

- Weather Resistance: Acrylic is highly resistant to UV rays and weathering, making it an excellent choice for outdoor projects like skylights, greenhouses, and outdoor signs.

- Scratch Resistance: Acrylic is more resistant to scratches compared to polycarbonate, maintaining a clear, smooth surface over time.

- Cost: Acrylic is generally more affordable than polycarbonate, making it a cost-effective solution for many projects.

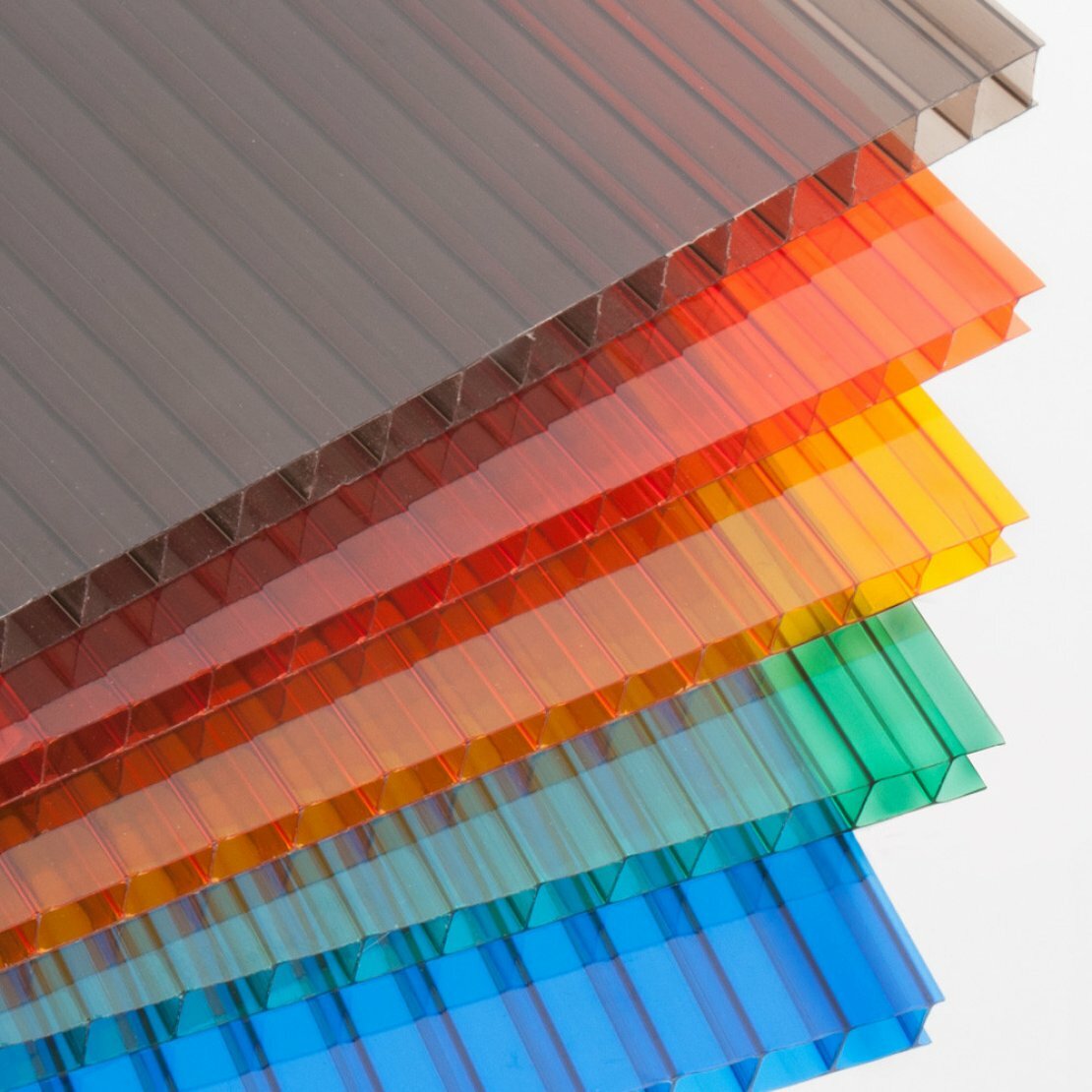

What is Polycarbonate?

Polycarbonate is another transparent thermoplastic but is known for its extreme toughness and high impact resistance. It's often found in applications where safety and durability are top priorities.

Key Properties of Polycarbonate:

- Strength: Polycarbonate is incredibly tough, boasting 250 times the impact resistance of glass. It’s virtually unbreakable, making it suitable for high-stress environments.

- Flexibility: Polycarbonate is more flexible than acrylic, allowing it to be easily bent and shaped without cracking, which is ideal for curved surfaces or complex designs.

- Heat Resistance: It can withstand higher temperatures than acrylic, making it suitable for industrial or high-heat applications.

- Optical Clarity: While still clear, polycarbonate has slightly lower light transmission (about 88%) compared to acrylic.

- Weight: Polycarbonate is also lightweight, though it is slightly heavier than acrylic.

- UV Protection: Polycarbonate requires special UV coating to prevent yellowing or degradation over time when exposed to sunlight.

Pros and Cons: Acrylic vs. Polycarbonate

Acrylic Advantages:

- Crystal Clear Transparency: Offers the highest level of light transmission, making it perfect for display cases, windows, and decorative applications.

- Scratch Resistance: Acrylic is less prone to surface scratches, ensuring a long-lasting, clear finish.

- UV Resistance: It naturally resists yellowing and degradation when exposed to sunlight, making it ideal for outdoor use.

- Affordability: Acrylic is more budget-friendly, especially for larger projects or applications where cost is a key factor.

- Ease of Workability: Acrylic is easier to cut and shape compared to polycarbonate, making it great for DIYers.

Acrylic Disadvantages:

- Lower Impact Resistance: While stronger than glass, acrylic is not as impact-resistant as polycarbonate, making it unsuitable for high-impact environments.

- Brittle Under Stress: Acrylic can crack or shatter under extreme pressure or when subjected to blunt force.

Polycarbonate Advantages:

- Unmatched Impact Strength: Polycarbonate’s incredible toughness makes it virtually unbreakable, ideal for safety barriers, protective shields, and glazing in high-traffic areas.

- Flexibility: Its flexibility allows it to be shaped into complex forms without breaking, perfect for curved or custom designs.

- Heat Resistance: Polycarbonate performs better under high temperatures and offers greater flame resistance than acrylic.

- High-Stress Applications: Polycarbonate is the material of choice for industrial settings, bulletproof windows, and security features where strength is critical.

Polycarbonate Disadvantages:

- Higher Cost: Polycarbonate tends to be more expensive than acrylic, especially for larger projects.

- Lower Scratch Resistance: Polycarbonate is more prone to surface scratches, which means it may require additional coatings or treatments to maintain its appearance.

- UV Degradation: Without UV protection coatings, polycarbonate can yellow and degrade with prolonged exposure to sunlight.

Common Applications: Acrylic vs. Polycarbonate

Acrylic is Ideal for:

- Home Décor: Acrylic’s clarity and ease of customization make it perfect for picture frames, furniture, and home accessories.

- Displays and Signage: It’s widely used for retail displays, signage, and exhibition stands due to its clear appearance and low cost.

- Windows and Skylights: For residential and light commercial projects, acrylic sheets are often used for windows and skylights.

- Aquariums and Terrariums: Acrylic’s optical clarity and ability to withstand moisture make it perfect for tanks and enclosures.

Polycarbonate is Ideal for:

- Safety Glazing and Barriers: Polycarbonate is commonly used for security windows, bank teller shields, and protective barriers due to its high impact resistance.

- Greenhouses: Its durability and resistance to impact make it an excellent choice for commercial and residential greenhouses.

- Automotive and Aerospace: Polycarbonate is used for aircraft windows, car headlight lenses, and other high-performance, high-stress applications.

- Bulletproof Glass and Riot Shields: In security applications, polycarbonate’s toughness is essential for creating protective glass and shields.

Which Material Should You Choose?

When deciding between acrylic and polycarbonate, the right choice depends on your project’s specific requirements. Here are a few key factors to consider:

- If Optical Clarity is Critical: Acrylic is the better choice due to its superior light transmission and smooth, glass-like appearance.

- For High-Impact Applications: Polycarbonate wins hands down. Its unbreakable nature makes it essential in environments where safety and durability are top priorities.

- Budget Considerations: Acrylic is typically more cost-effective, making it ideal for large projects or applications where affordability is important.

- Outdoor Use: Both materials work well outdoors, but acrylic’s natural UV resistance gives it an edge unless polycarbonate is UV-coated.

- For DIY Projects: Acrylic is easier to cut and handle for most DIY projects, whereas polycarbonate may require more specialized tools for cutting.

Conclusion

Both acrylic and polycarbonate offer significant advantages, but understanding their differences will help you choose the right material for your project. Acrylic provides crystal-clear visibility, affordability, and versatility, making it perfect for display cases, signage, and home décor. On the other hand, polycarbonate’s unparalleled strength and flexibility make it the go-to material for safety barriers, high-impact windows, and industrial applications.

By considering the specific demands of your project, you can make a well-informed decision that ensures durability, functionality, and aesthetic appeal.